Kiln Automation

Smart Programming for Kiln Precision Control.

We design firmware-ready firing schedules, sensor maps, and monitoring workflows tailored to your studio. The result is consistent color, reduced waste, and confident scaling.

Precision

Digital tooling for artisan control.

Material science

Glaze + firing workflows engineered.

Immersive

VR previews before the first kiln run.

Why automate

Benefits

- Reduce firing failures by 90%

- Energy savings through optimized cycles

- Consistent color and glaze outcomes

Compatible with popular kiln models used in Egyptian studios.

Capabilities

Automation features

Custom firing curves

Profiles tuned to clay bodies, glaze chemistry, and kiln size.

Remote monitoring

Sensor dashboards and alerting for temperature and humidity shifts.

Predictable color outcomes

Repeatable heat soak stages for stable glaze and pigment results.

Energy optimization

Optimized ramp schedules reduce power waste without sacrificing quality.

Multi-kiln orchestration

Coordinate parallel firings across production schedules.

Compliance-ready logging

Structured data logs for quality assurance and client reporting.

Success stories from local glass studios

Case studies

Nile Gallery Series

30% faster prototyping with automated kiln cycles and stabilized glaze viscosity.

Zamalek Atelier

Consistent glaze profiles across 18 unique forms with fewer failed firings.

Desert Light Studio

Reduced firing time by 22% while maintaining spectral consistency.

Museum Edition Run

Archival-quality firing logs for limited collector pieces.

Live automation sequences

Demo videos

Live Automation Sequence

Watch a full firing cycle in real time.

Telemetry Dashboard

Remote monitoring walkthrough.

Installation, training, ongoing updates

Support

Installation

On-site or remote setup of automation scripts.

Training

Hands-on instruction for your studio team.

Ongoing Updates

Firmware and profile updates as needed.

Infrastructure

Telemetry & stack

Thermocouple grid

Distributed probes for accurate thermal mapping.

Glaze viscosity index

Data-driven indicators for color stability.

Humidity checkpoints

Environmental monitoring for drying control.

Batch analytics

Cross-run comparison and anomaly detection.

Behind the fire

Automation gallery

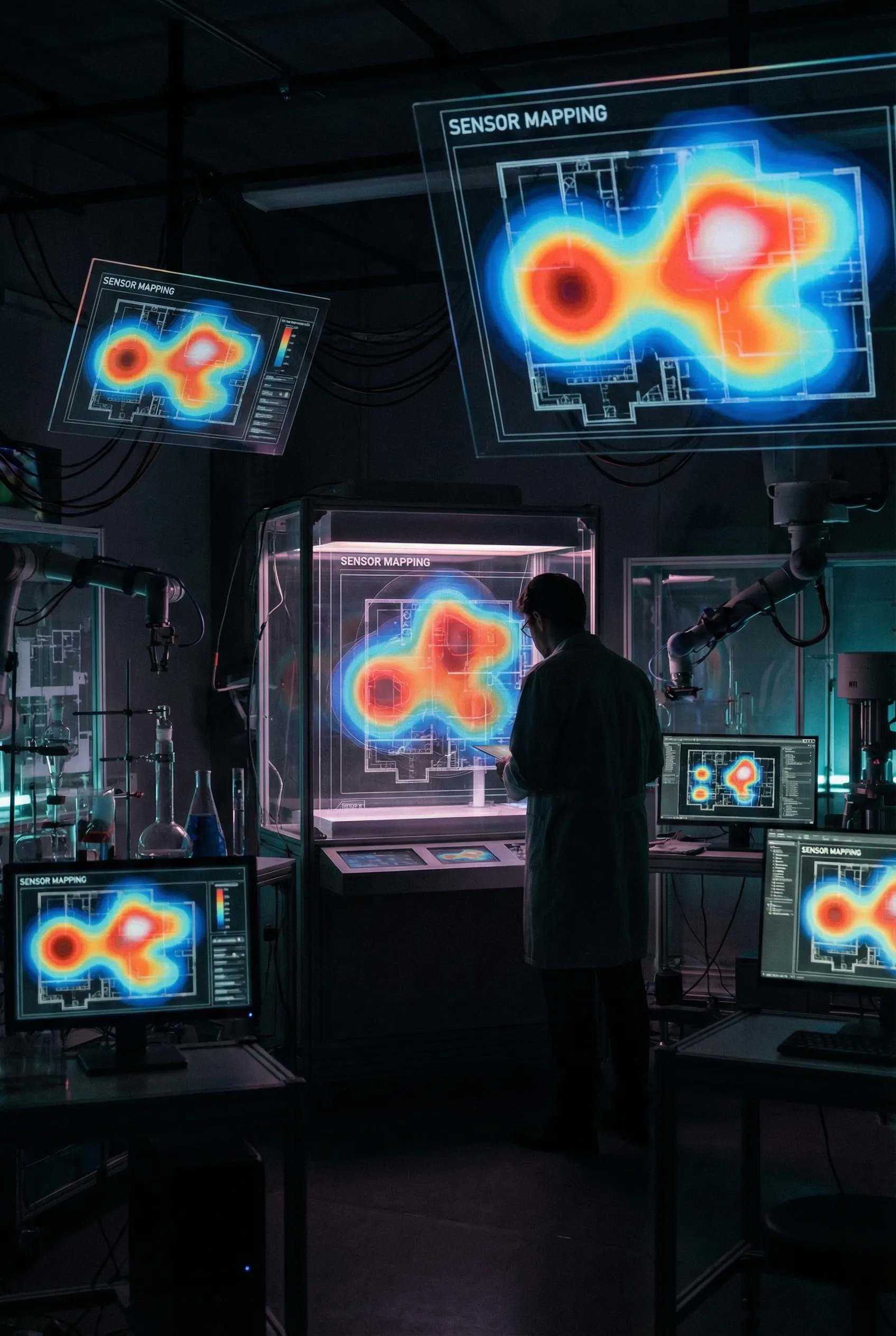

Telemetry Wall

Live dashboards for active firings.

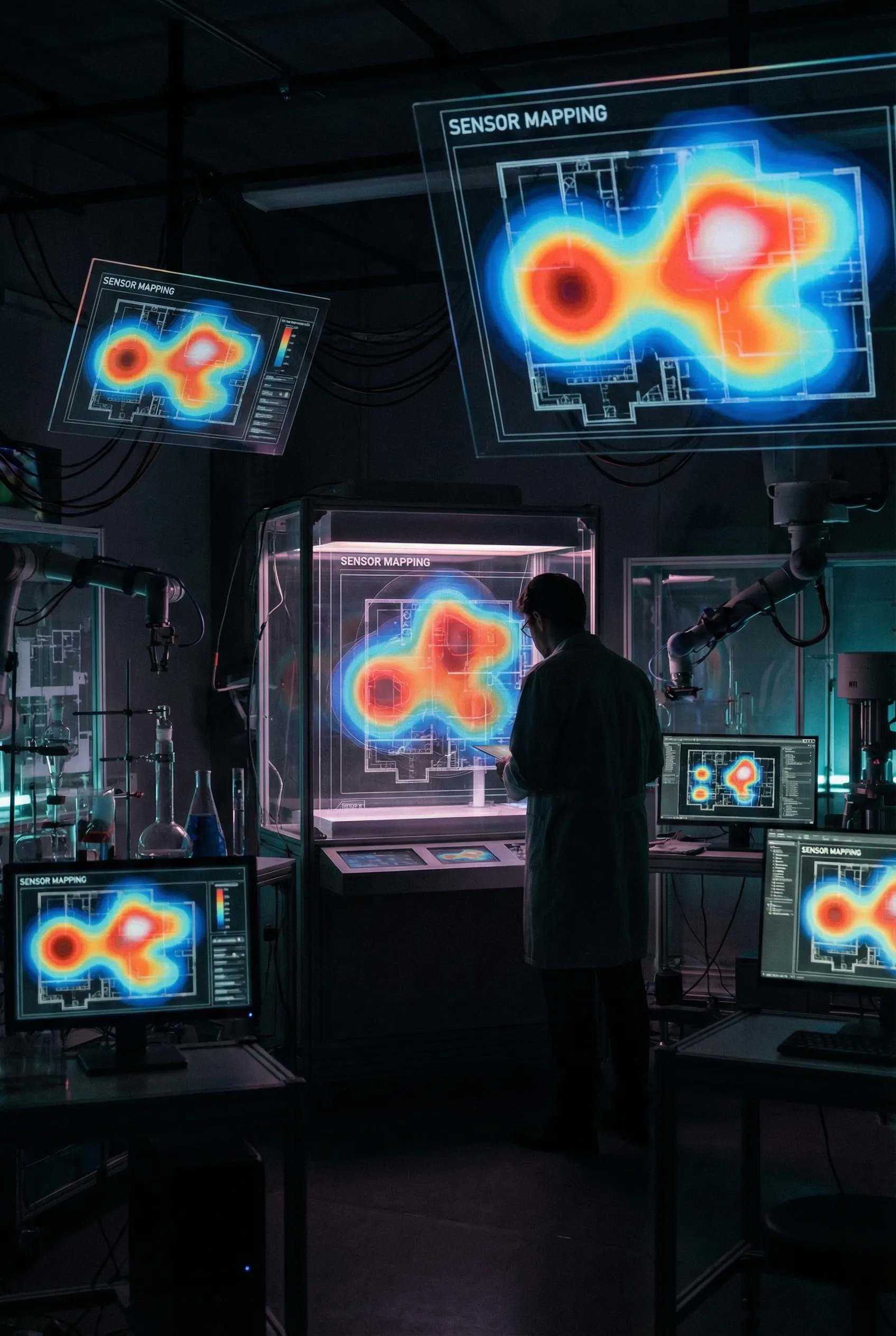

Sensor Mapping

Heat mapping across kiln chambers.

Cycle Programming

Custom scripts for complex firing stages.

Glaze Lab

Testing outcomes aligned with automation data.