3D Modeling

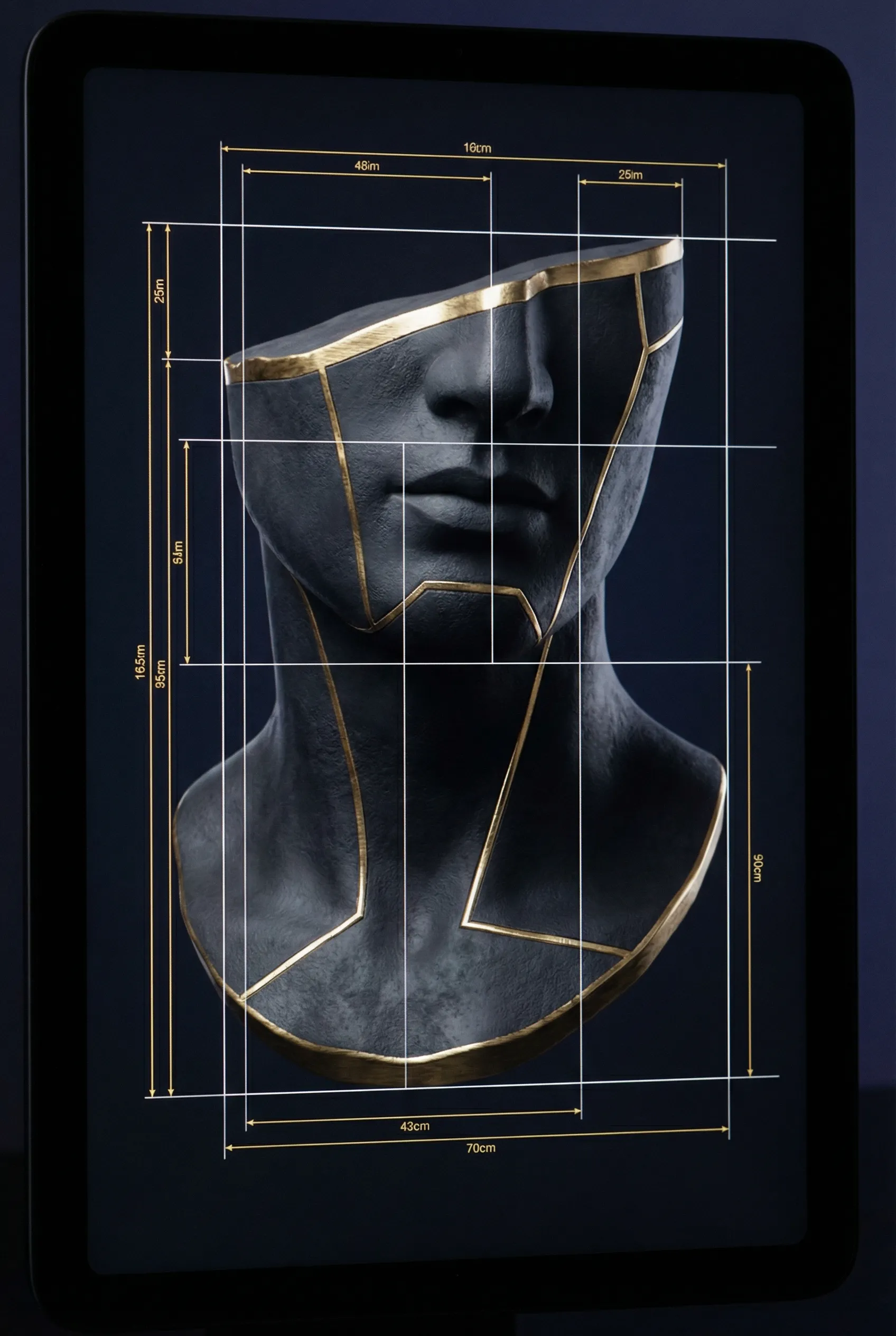

Precision 3D Modeling for Ceramics and Glass.

From early ideation to production-ready geometry, we translate your vision into manufacturing-grade assets. Our models consider wall thickness, shrinkage, and tooling constraints.

Precision

Digital tooling for artisan control.

Material science

Glaze + firing workflows engineered.

Immersive

VR previews before the first kiln run.

From concept to STL

Process overview

From concept sketches to printable STL files—we handle every step of the digital fabrication pipeline.

Discovery & references

We gather heritage references, usage context, and production constraints.

Parametric sculpting

Geometry is built with thickness, shrinkage, and tooling in mind.

Material simulation

Digital tests predict glaze behavior and highlight stress points.

Production handoff

Final files, mold specs, and fabrication notes are delivered.

Before & after

Case studies

Ankh Vessel Series

Parametric geometry tuned for slip casting with a refined structural spine.

Lotus Glassware

Lightweight forms optimized for furnace cycles and optical clarity.

Royal Studio Molds

Precision molds ready for CNC milling and rapid form iteration.

Desert Relief Tiles

Patterned tiles with controlled depth for expressive wall installations.

Industry-leading software

Tools used

- Rhino / Grasshopper for parametric surfaces

- Blender for organic sculpting

- Material simulation for glass and glaze

- STL/OBJ export for CNC and 3D printing

Feedback from Egyptian artisans

Client testimonials

“They turned my hand sketches into production-ready molds. The attention to wall thickness and shrinkage was exceptional.”

Fatima Khalil

Ceramics Artist, Cairo

“Our lotus series went from concept to furnace in half the usual time. The 3D models were fabrication-perfect.”

Hassan Mahmoud

Glass Studio Owner

Pricing

Engagement tiers

Prototype

$1,200

Ideal for single hero pieces or limited runs.

- • 1–2 hero forms

- • 2 revision rounds

- • 3D-ready export files

- • Material behavior notes

Studio

$2,900

Designed for ongoing studio collections.

- • 5–8 hero forms

- • Automation consult

- • Material presets

- • Gallery staging guidance

Forge

Custom

End-to-end collaboration for large collections.

- • Full collection modeling

- • VR review sessions

- • On-site training

- • Production handoff kit

Surface & form

Portfolio gallery

Form Study

Iterative sculpting with proportion controls.

Surface Detail

Texture mapping for heritage-inspired patterns.

Print Preview

Preview of forms before CNC or 3D printing.

Collection Layout

Series planning for cohesive gallery sets.